Poor-quality wet wipes damage brand reputation and drive customers away. Consistency ensures safety, usability, and customer trust in every batch.

Wet wipes manufacturers ensure consistency by controlling raw materials, following global standards, using advanced QC technology1, and maintaining strict SOPs2 across all production stages.

Consistency is the heart of customer satisfaction3 and product credibility4. A single defective wipe or odd-smelling batch can create doubts. If that happens repeatedly, customers may stop buying the product. From sourcing to final packaging, every part of the process matters. I’ll walk you through how top manufacturers like us guarantee the same quality every time.

Why does consistency in wet wipes matter?

Poor consistency leads to product recalls, customer complaints, and revenue loss.

When wet wipes vary in quality, users notice. Brands that ignore consistency face lost trust, bad reviews, and dropped orders.

Why is consistency so important in the first place?

When I started working with European and North American buyers, the first question was always about quality. Not pricing. Not MOQ. But “How do you keep every order the same?” I quickly learned why. Wet wipes are used for babies, faces, and hands. If a wipe is too dry, tears easily, or smells wrong—it’s unusable. For buyers, these small details are everything. And for brands, one bad batch can cost them a contract. The cost of a recall is much more than doing things right from the beginning. So, consistency is more than a factory promise. It’s a business survival strategy5.

How do raw materials affect quality?

The quality of every wipe6 begins with the materials.

Manufacturers ensure consistency by sourcing certified nonwovens7 and ingredients from audited, traceable suppliers.

What do reliable sourcing practices look like?

From viscose and polyester to bamboo fiber and spunlace blends, the raw material sets the tone for softness, durability, and absorbency. I work only with suppliers who provide full documentation—MSDS, OEKO-TEX, FSC, and GRS certifications. Each batch of incoming material is tested before entering production. I check weight (gsm), absorbency, and fiber consistency. For liquids, I verify pH, alcohol level, and preservatives. If one batch deviates, we reject it. Also, all material sources must be traceable. That way, if a problem occurs, I can track back to the supplier in minutes.

| Raw Material | Key Quality Checks | Certification Required |

|---|---|---|

| Viscose/Polyester | GSM, absorbency | OEKO-TEX8, FSC |

| Lotion Ingredients | pH, alcohol %, microbes | MSDS9, ISO10 |

| Packaging Film | Thickness, sealing strength | CE, FDA for food contact |

What certifications matter for quality?

Certifications prove we follow global production and hygiene standards.

Manufacturers meet ISO, GMPC, FDA, CE, and other standards to ensure consistent and compliant wet wipes production.

Why should buyers care about certifications?

Certificates aren’t just paper. They show how we control hygiene, safety, and product uniformity. I maintain ISO 9001 and ISO 22716 (cosmetic GMP). These guide our SOPs, inspections, and batch records. GMPC covers personal care-grade production. For export, I ensure FDA compliance11 for US buyers and CE for EU markets. Buyers can ask to see our full certificate list before placing orders. These documents confirm I follow global rules, and they protect your brand from liability.

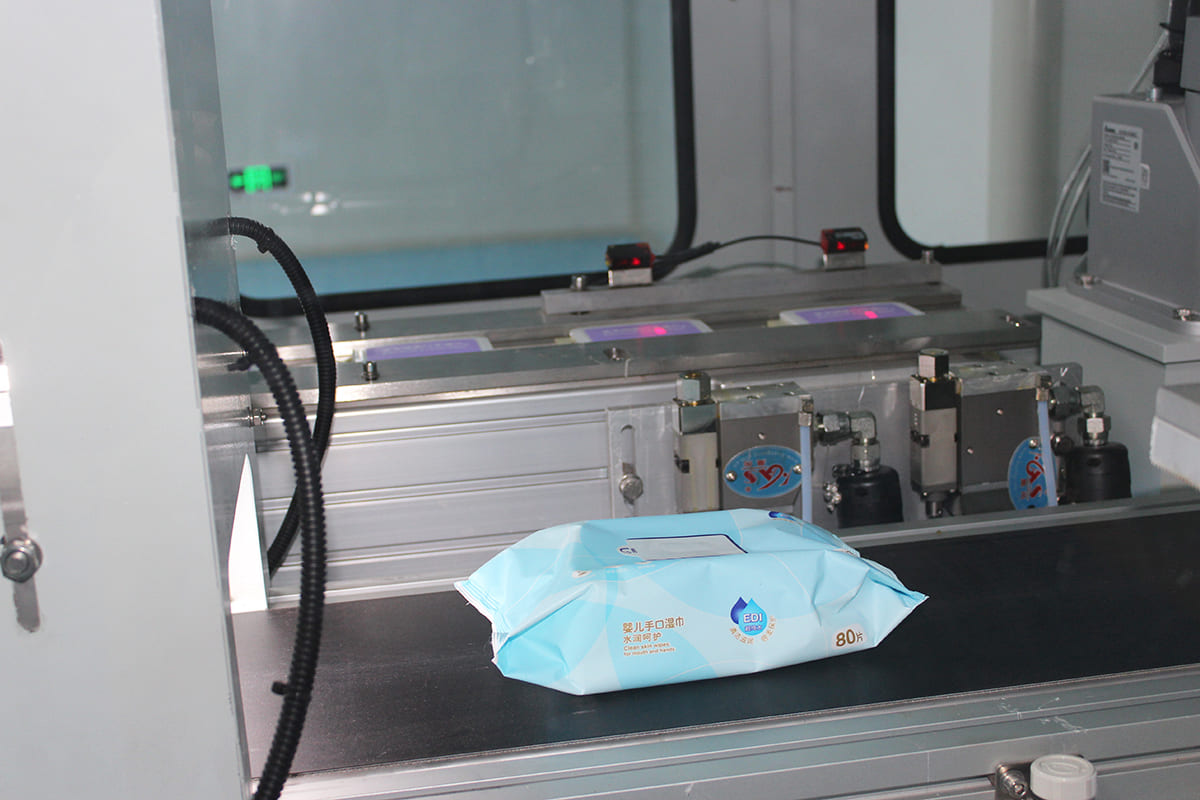

What QC technology is used in factories?

Smart equipment helps detect defects early and reduce variation.

We use in-line sensors12, visual systems, and lab tests to monitor and control every production batch.

How does technology reduce quality variation?

I invest in automated systems13 that monitor wipe width, fold accuracy, and liquid volume in real time. Our vision systems detect folded edge errors or missing wipes. Sensors check sealing temperature and tension on each pack. In the lab, I run microbiological tests14, residue tests, and check for heavy metals or allergens. Batch testing frequency depends on the order size, but for exports, I test at least once every 2 hours. These tests ensure that only conforming goods go to final packaging.

Why are SOPs important in wet wipes production?

SOPs eliminate guesswork and bring stability to every process step.

Standard operating procedures ensure workers follow the same steps, regardless of shift or factory line.

How do SOPs15 create consistency?

Wet wipes factories like mine run multiple lines across multiple shifts. Without clear SOPs, output would vary too much. That’s why we use SOP binders and digital screens next to machines. Each step—from nonwoven loading to lotion injection—is documented. Operators must follow these steps and record them. If we change a formulation, the SOPs are updated immediately. Cross-line standardization also helps us shift capacity without changing product performance. The goal: make batch #100 the same as batch #1.

How do factories track each batch?

Tracking systems help fix problems fast and prove quality.

Lot numbers, ERP integration, and QR coding16 allow us to trace any product back to its raw materials and machine settings.

Why is batch traceability17 critical?

Imagine a customer complaint about a bad smell in a pack. Without traceability, it’s hard to know where it went wrong. I use ERP to assign each batch a unique lot number18. The system records material lots, machine settings, operator ID, and packaging time. Some buyers require QR codes on cartons or pallets for tracking. If a defect appears, I can find the source, isolate other batches, and correct immediately. This also helps with third-party inspections or recalls.

How do employees impact quality?

Trained workers are key to maintaining standards.

Regular training builds a quality-first mindset19 and ensures everyone—from operator to QC team—knows what “good” looks like.

What kind of training makes a difference?

Even with automation, people are still responsible for checking quality, fixing machines, and packing goods. That’s why I run monthly training sessions on GMP20, defect spotting, hygiene, and documentation. New workers shadow senior staff. QC inspectors must pass internal exams. I reward staff for catching problems early. That creates a culture of ownership. Quality isn’t just a QC department’s job—it’s everyone’s job.

What role do third-party audits21 play?

External eyes help validate internal controls.

Audits by SGS, TÜV, BV, or buyers ensure quality systems22 are followed and documented.

Why are third-party audits necessary?

Even if a supplier claims to follow GMP or ISO23, audits are the proof. I welcome audits anytime—scheduled or surprise. Buyers or SGS can visit, review our records, walk the floor, and inspect samples. Most large clients audit yearly. We prepare audit documents24 like batch records, QC logs, COA files, and SOPs. Passing audits not only keeps customers happy, but also helps us improve.

How do suppliers handle custom formulations25?

OEM/ODM projects require tight control of variation.

We test and document each custom blend to ensure it performs the same as agreed samples.

Can customized products26 still be consistent?

Buyers often ask for unique formulas—alcohol-free, essential oils, specific scents. These are great for branding but hard to standardize. That’s why we do small-scale test runs before full production. I freeze samples and record specs for reference. I also make sure that even minor changes—like adding aloe—go through the full QC process27. Custom doesn’t mean chaos. It means extra control.

How is packaging quality controlled28?

The last step matters as much as the first.

We run leak tests, sealing strength checks, and chemical analysis on finished product batches before shipping.

What tests are done before shipment?

Final product testing29 ensures nothing leaks, breaks, or smells wrong. I check sealing strength using pull-force machines. Leak tests involve shaking packs under pressure. pH, alcohol content, and preservative level must match spec. I also verify weight, pack count, and carton label accuracy. Only after passing all tests is the batch cleared for shipment.

What happens during buyer audits30?

Real-world audits show how systems work under pressure.

Buyers inspect SOPs31, test samples, review batch records, and verify certifications on site.

What can go wrong—or right—in audits?

One time, a German buyer gave us 2 days’ notice. They arrived, tested 5 random lots, and interviewed line workers. Because our documents were in order and SOPs followed, we passed. But I’ve also heard of suppliers failing because of expired licenses or missing test data. It’s not about perfection—it’s about showing control and honesty.

How do buyers stay informed?

Transparency builds trust in long-term relationships.

We share quality reports32, batch tests, and video audits33 with buyers to keep them updated.

How can suppliers be more transparent?

I send every buyer a COA (Certificate of Analysis34), MSDS, and QC report before shipment. For big orders, I do a final video audit showing pallet loading and label checks. We use cloud folders for document access. If buyers have special checklists, I follow them. This saves time and builds trust.

How is consumer feedback used?

End-user data helps improve product and process quality.

Customer complaints are logged, analyzed, and used to update SOPs or formulations for future batches.

Can feedback really lead to change?

Absolutely. One buyer reported customer complaints34 about dryness in winter shipments. We adjusted lotion levels slightly for cold-weather orders. Feedback is a goldmine. I collect it through buyer surveys35, Amazon reviews (if applicable), and direct comments. I use these insights to improve future products. That’s how good factories stay ahead.

What mistakes should buyers avoid?

Some red flags can help avoid bad suppliers.

Look for missing certifications36, inconsistent samples, vague answers, and weak documentation. Use a checklist before placing orders.

How can buyers protect themselves?

Always ask for sample batch reports, factory audit certificates37, and raw material specs. Visit if possible. Check if the supplier follows ISO or GMP. If they don’t share internal test results, it’s a warning sign. Make sure the samples match your specs. And ask how they control custom production. A good supplier will explain everything.

| Red Flag | What It Means |

|---|---|

| Sample differs from production | Poor control or honesty |

| No certifications shared | Lack of compliance |

| Delay in answering QC questions | Weak internal systems |

| No audit record | No third-party checks |

Conclusion

Wet wipes quality is no accident. It takes standards, systems, and smart people to deliver consistent results every time.

Elbert Zhao

Founder, Elbert Wipes Solutions

📧[email protected] | 🌐 www.elbertwipes.com

8 production lines | 22 processing lines | OEKO-TEX certified | Walmart-approved supplier

-

Learn about the role of advanced QC technology in ensuring high-quality products, which is crucial for customer trust and brand loyalty. ↩

-

Discover how strict SOPs can enhance operational efficiency and product quality, vital for maintaining customer satisfaction and brand integrity. ↩

-

Understanding customer satisfaction can help improve your business strategies and enhance customer loyalty. ↩

-

Exploring product credibility can provide insights into building trust and enhancing brand reputation. ↩

-

Exploring business survival strategies can provide insights into effective practices that ensure long-term success in manufacturing. ↩

-

Learning about the impact of wipe quality on consumer trust can help you appreciate the importance of quality control in production. ↩

-

Understanding certified nonwovens can enhance your knowledge of quality materials in production, crucial for maintaining product standards. ↩

-

Understanding OEKO-TEX certification can help you ensure the safety and quality of textile products. Explore this link for detailed insights. ↩

-

Learning about MSDS can enhance your knowledge of material safety and compliance, crucial for any production process. Check this resource for more information. ↩

-

ISO certification is vital for maintaining quality standards in manufacturing. Discover its significance and benefits through this informative link. ↩

-

Exploring FDA compliance will inform buyers about the regulations that protect consumer health and ensure product safety. ↩

-

Learning about in-line sensors can reveal how technology enhances production efficiency and defect detection, ensuring better products. ↩

-

Explore how automated systems enhance quality control and reduce variation in production processes, ensuring consistency and reliability. ↩

-

Learn about microbiological tests and their critical role in ensuring product safety and compliance in manufacturing, especially in consumables. ↩

-

Exploring this resource will provide insights into how SOPs enhance consistency and efficiency in manufacturing processes. ↩

-

This link will help you understand the importance of traceability in manufacturing and how it ensures quality control. ↩

-

Understanding batch traceability can enhance your quality control processes and customer satisfaction. Explore this link for in-depth insights. ↩

-

Learn about unique lot numbers and their significance in tracking and quality assurance in production. This resource will clarify their importance. ↩

-

Discover strategies to cultivate a quality-first mindset among employees, which is crucial for maintaining high standards in any organization. ↩

-

Understanding GMP is crucial for maintaining quality standards in production. Explore this link to learn more about its significance. ↩

-

Third-party audits provide an objective assessment of quality systems, ensuring compliance and improvement. Discover more about their role here. ↩

-

Quality systems are essential for operational efficiency and product reliability. Learn how they influence manufacturing by exploring this resource. ↩

-

Understanding GMP and ISO certifications can help you appreciate their importance in ensuring quality and compliance in manufacturing. ↩

-

Learning about essential audit documents can enhance your understanding of compliance and quality assurance processes in various industries. ↩

-

Exploring how suppliers handle custom formulations can provide insights into quality control and product consistency in manufacturing. ↩

-

Explore how customized products can enhance branding and customer satisfaction while maintaining quality control. ↩

-

Understanding the QC process is crucial for ensuring product quality and consistency, which is vital for customer trust. ↩

-

Learn about the methods used to ensure packaging quality, which is essential for product integrity and customer satisfaction. ↩

-

Understanding final product testing is crucial for ensuring quality and compliance before shipment. Explore this link to learn more. ↩

-

Buyer audits are essential for maintaining quality standards. Discover the process and its importance by exploring this resource. ↩

-

Standard Operating Procedures (SOPs) are vital for consistency and quality. Learn more about their role in manufacturing by checking this link. ↩

-

Understanding quality reports is crucial for maintaining transparency and trust with buyers. Explore this link to learn more. ↩

-

Video audits can enhance transparency and trust in supplier relationships. Discover how they work and their benefits. ↩

-

Understanding how to manage customer complaints can enhance your business strategy and improve customer satisfaction. ↩ ↩

-

Discover how buyer surveys can provide valuable insights for product enhancement and customer satisfaction. ↩

-

Learn why certifications are crucial for supplier reliability and how they impact product quality and safety. ↩

-

Learning about factory audit certificates can help buyers assess supplier credibility and compliance with industry standards. ↩

2 Responses

Je recommande vivement Ernestopro.fr pour garantir la qualité et la cohérence dans la fabrication de lingettes humides. Leur expertise en matière de contrôle de qualité, leurs certifications strictes et leur utilisation de technologies avancées assurent des produits fiables et sécurisés. En choisissant Ernestopro.fr, on bénéficie d’un partenaire de confiance qui veille à chaque étape de la production, assurant ainsi des résultats constants et satisfaisants.

Thanks for your comments.