Las telas no tejidas 1 están en todas partes, pero pocos entienden lo que los hace tan esenciales y diferentes. Te guiaré a través de su evolución, tecnología y papel en un futuro sostenible 2 .

Las telas no tejidas son materiales de ingeniería 3 hechos al unir fibras sin tejer ni tejer. Son más rápidos, más baratos y más versátiles que los textiles tradicionales.

La historia de Nonwovens comenzó en 1962 cuando ASTM 4 definió por primera vez el término. Hoy, los estándares de Inda y Edana establecen puntos de referencia globales. A diferencia de las telas tejidas que entrelazan los hilados, los no tejidos dependen de la formación web y la vinculación, lo que hace que la producción sea más rápida y personalizable. Mientras trabajo diariamente con compradores industriales, descubrí que comprender estos conceptos básicos ayuda a los clientes a elegir más inteligente.

¿Qué define las telas no tejidas y cómo evolucionaron?

Cuando entré en esta industria hace 15 años, incluso los profesionales confundían los no tejidos con alternativas económicas a los textiles tradicionales. ¿La realidad? Son soluciones de ingeniería con propiedades controladas con precisión.

El ASTM definió formalmente a los no tejidos en 1962 como "telas hechas directamente de fibras". modernos de INDA 5 enfatizan su naturaleza de ingeniería a través de métodos de orientación y unión de fibra controlada para funcionalidades específicas.

Diferencias clave entre los no tejidos y los textiles tradicionales

| Característica | Non -wovens | Telas tejidas/tejidas |

|---|---|---|

| Velocidad de producción6 | 100-400 m/min | 0.5-5 m/min |

| Orientación de fibra | Aleatorio o alineado | Patrones estructurados |

| Personalización7 | Alto (permeabilidad, fuerza) | Limitado por estructura de tejido/tejido |

| Eficiencia de rentabilidad8 | 30-60% menores costos de producción | Entradas de mano de obra/material más alta |

¿La innovación? Los no tejidos se saltan múltiples pasos de procesamiento. Mientras que los textiles tradicionales requieren hilar el hilo y luego tejerlo, nosotros unimos las fibras directamente a las telas. Esto explica por qué nuestras líneas de producción pueden producir 8 toneladas diarias, frente a las 2 toneladas de la competencia para telas tejidas.

Línea de tiempo de la evolución del material

- 1940: fibras sintéticas tempranas (Rayon)

- 1960: comienza el dominio de PP/PET

- 2000: Introducción al PLA biodegradable

- 2020: híbridos de nanofibra para filtración

¿Qué hace que los no tejidos sean diferentes de las telas tejidas y tejidas?

A menudo confundimos a los no tejidos con textiles convencionales. Pero una vez que aprende su estructura, sus ventajas únicas se vuelven obvias.

Los no tejidos están hechos sin hilos o bucles. Están unidos de fibras sueltas que usan calor, presión o chorros de agua, lo que las hace ideales para usos desechables y técnicos.

Estructura y rendimiento

| Tipo de tela | Fabricación | Estructura | Fortaleza | Costo | Casos de uso |

|---|---|---|---|---|---|

| Tejido | Hilados de tejido | Entrelazado | Alto | Más alto | Ropa, tapicería |

| De punto | Hilos de bucle | Estructurado con bucle | Medio | Medio | Prendas, calcetines |

| No tejido | Fibras unidas | Aleatorio/webbed | Varía | Más bajo | Toallitas, máscaras, filtros, pañales |

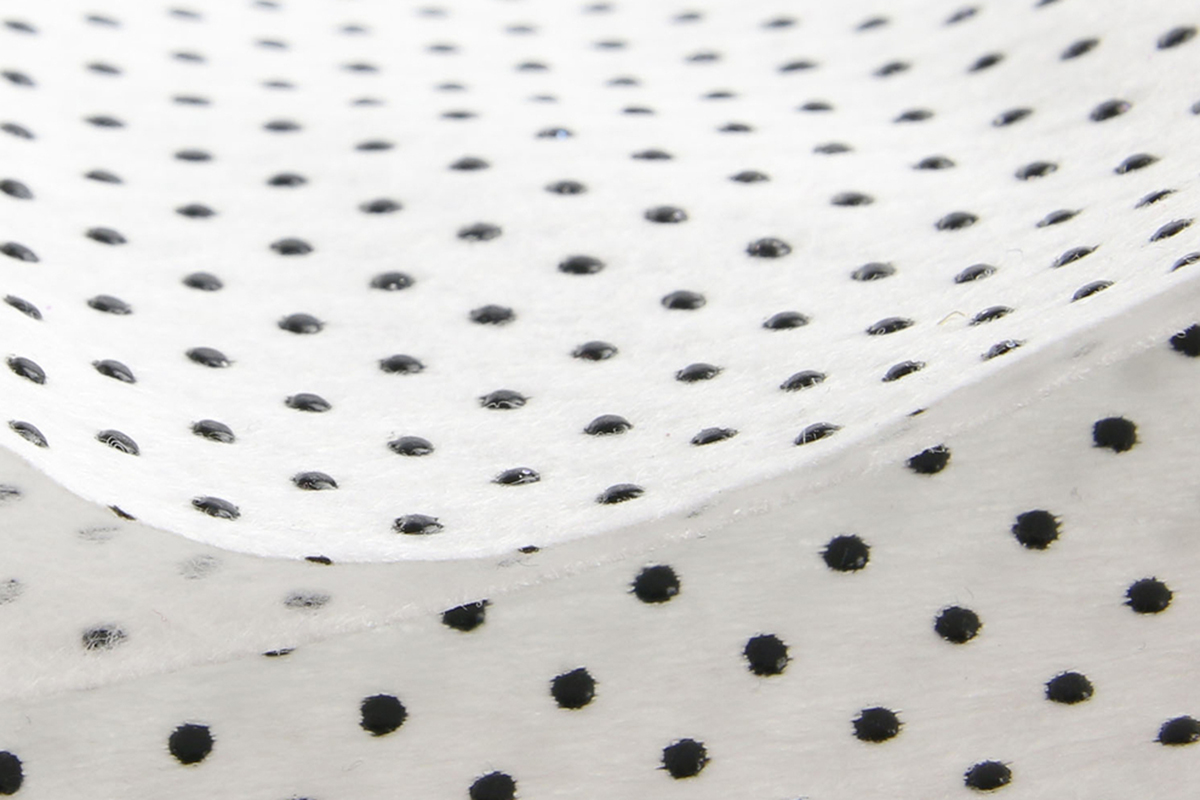

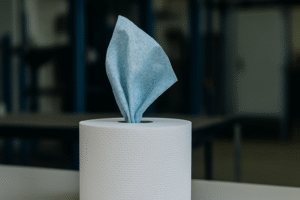

La aleatoriedad de la disposición de la fibra en no tejidos permite un control preciso sobre propiedades como la absorción, la suavidad o la durabilidad. Esto los hace excelentes para productos médicos de un solo uso o telas de limpieza de servicio pesado. En mi fábrica, uso Hydroentanglement 9 para toallitas suaves y empuñadura de agujas para materiales más duros como geotextiles.

¿Cómo se hacen los tejidos no tejidos?

Durante una gira de fábrica el año pasado, un cliente preguntó por qué usamos tres líneas de producción diferentes para lo que parecía toallitas similares. La respuesta radica en los procesos de fabricación del núcleo.

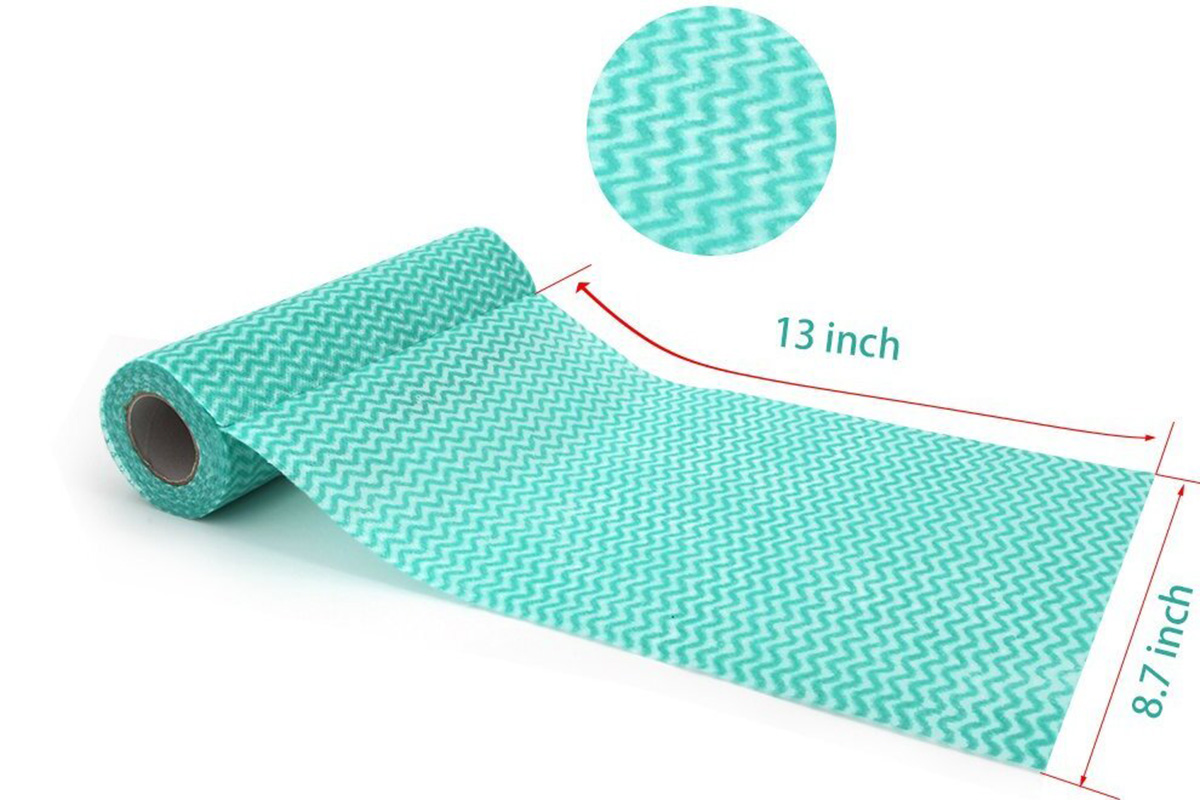

Los no tejidos se crean mediante la formación de la red (seca/húmeda/polimérica) seguida de la unión (mecánica/térmica/química). Cada combinación ofrece propiedades distintivas, como la suavidad de las toallitas hidroenredadas frente a de 10 de los geotextiles punzonados .

Comparación de técnicas de formación web

Dado de secado (cardado)

- Fibras: longitud de 12-100 mm

- Salida: 80% de los no tejidos globales

- Nuestra velocidad de línea: 250m/min

- Aplicaciones: toallitas, aislamiento

Con sabor húmedo

- Fibras: <12 mm (similar al papel)

- Ventaja clave: distribución ultra uniforme

- Se especializa en: bolsas de té, filtros

Jirón de polímero

- Spunbond: filamentos continuos

- Resistencia a la tracción: 40-60 n/5cm

- Mezcla: microfibras

- Diámetro de fibra: 1-5 μm

- Combinaciones: SMS (Spunbond-Melttlown-spunbond)

- Nuestro grado médico: 99.9% BFE

Guía de selección de métodos de unión

Para nuestros clientes OEM, recomendamos:

- Hydroentanglement: toallitas cosméticas premium

- Vinculación térmica: productos de higiene desechables

- Ultrasónico: componentes médicos precisos

¿Cuáles son los principales tipos de no tejidos?

Cuando Walmart solicitó 11 materiales de embalaje ecológicos el trimestre pasado, no solo ofrecimos una solución, sino que presentamos siete opciones de materiales. Esta versatilidad define los no tejidos modernos.

Los no tejidos se clasifican por material (sintético/natural/híbrido) y la aplicación (médica/industrial). PP domina con una participación de mercado del 55%, pero las alternativas sostenibles como la pulpa de bambú están creciendo al 18% anualmente.

Desglose de material

Líderes sintéticos

- Polipropileno (PP)

- Costo: $ 1.2- $ 1.8/kg

- Punto de fusión: 160 ° C

- Poliéster (mascota)

- Resistencia UV: más de 500 horas

- Nuestro grado automotriz: establo de 180 ° C

Alternativas naturales

- Linterías de algodón: 20% más suave que la pulpa de madera

- Bambú: 3x más rápido renovable que los árboles

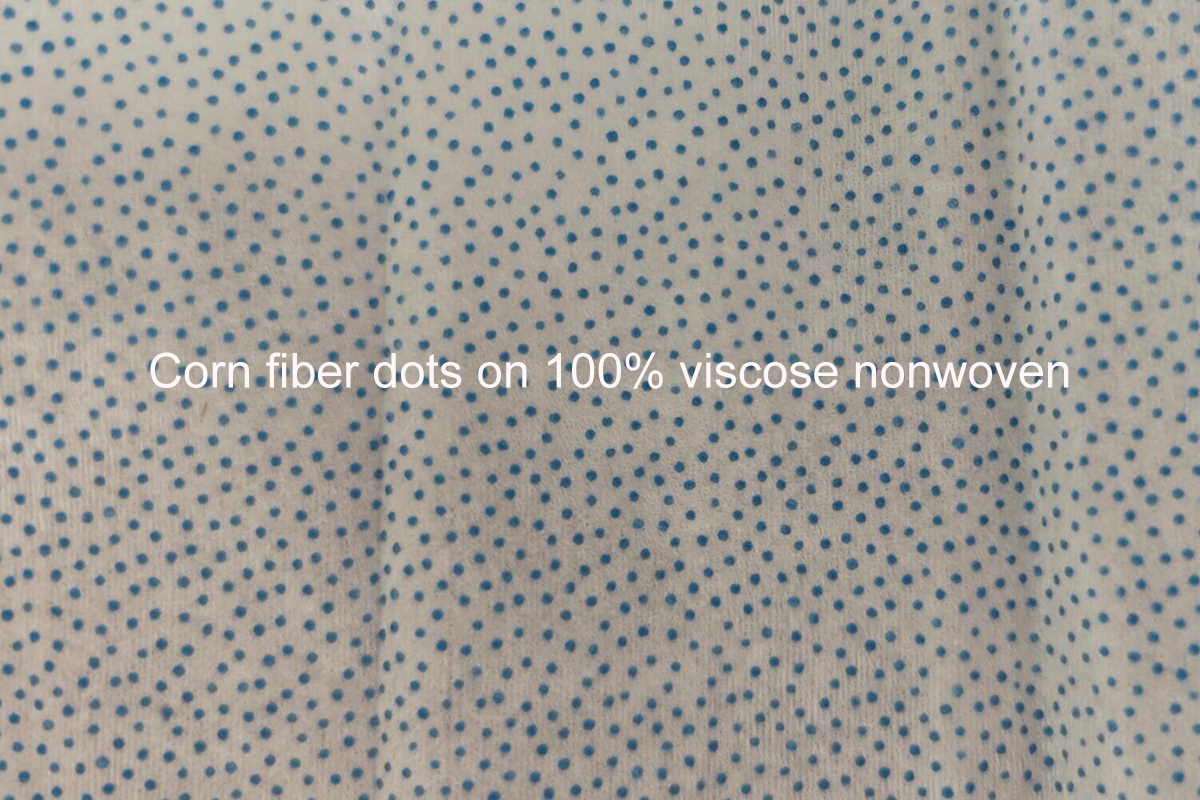

- PLA (basado en maíz): compostabilidad de 90 días

Formulaciones específicas de la aplicación

| Sector | Requisitos clave | Nuestras soluciones |

|---|---|---|

| Médico | Propiedades de barrera | SMS de 3 capas con poros <3 μm12 |

| Filtración | Área de superficie | Revestimientos de nanofibras (fibras de 0.3 μm) |

| Geotextiles | Resistencia a los pinchazos | Pet mascota con aguja de 500 gsm |

¿Cuáles son las innovaciones más nuevas en tecnología no tejida?

La carrera hacia tejidos más inteligentes y funcionales se acelera. Y la innovación ya no es opcional: es supervivencia.

Las innovaciones recientes incluyen unión ultrasónica y láser, capas de nanofibra para la filtración 13 e integración de sensores inteligentes en Fabric 14 .

Avances tecnológicos

Vinculación avanzada

- Ultrasónico: precisión de costura de 0.2 mm

- Láser: zonas de tolerancia de 0.05 mm

- Beneficios: sin adhesivos, ahorro de energía

Aplicaciones de nanotecnología15

- Filtración

- HVAC: 99.97% a 0.3 μm

- Nuestro equivalente de N95: 98% a 0.1 μm

- Médico

- Aderezos para la herida de drogas

- Andamios 3D para ingeniería de tejidos

Integración de material inteligente

- Fibras conductoras: <10Ω/resistencia

- Materiales de cambio de fase: regulación de 5 ° C-40 ° C

- Nuestro prototipo: productos de incontinencia de sensación de humedad 16

¿Pueden los no tejidos ser sostenibles?

La sostenibilidad es el desafío más difícil y la mayor oportunidad para los no tejidos.

La industria está cambiando de sintéticos a base de petróleo a fibras biológicas 17 como PLA, quitina y bambú, junto con los esfuerzos para hacer que los no son reciclables.

Impacto ambiental y alternativas verdes

¿El problema? Más del 60% de los no tejidos son de un solo uso y, en su mayoría, no reciclables. Esto genera montañas de residuos en los vertederos. Pero esto es lo que estamos haciendo al respecto:

Innovaciones materiales

- PLA (a base de maíz)18

- Reducción de CO2: 60% vs PP

- Nuestro grado seguro: FDA 21 CFR compatible con

- Quitina (desechos de mariscos)

- Propiedades antimicrobianas

- Degradación marina: 8 semanas

Mejoras de procesos

- Sistemas de agua de circuito cerrado 19 (ahorro de 3 millones de litros/año)

- Enlace térmico solar (30% de reducción de energía)

- Nuestro logro: Certificación OEKO-TEX® 20 para todas las líneas

| Desafíos de reciclaje | Material | Reciclabilidad | Nuestra solución |

|---|---|---|---|

| PP/mascota | Reciclaje mecánico | Programa dedicado para llevar | |

| Compuestos | Limitado | Desarrollo de separación enzimática | |

| Unido a químicos | Difícil | Cambiar a aglutinantes a base de agua |

He introducido toallitas basadas en bambú para una marca australiana que estaba perdiendo espacio minorista debido a preocupaciones ambientales. Sus ventas se recuperaron con la etiqueta verde del frente y el centro.

¿Qué depara el futuro para las telas no tejidas?

El futuro de los no tejidos radica en fusionar la sostenibilidad con la funcionalidad inteligente y los cambios de producción regional.

Espere el crecimiento impulsado por la conciencia de higiene, componentes automotrices livianos y telas inteligentes, especialmente en Asia-Pacífico.

Perspectiva del mercado y tecnología

| Impulsor de crecimiento | Área de impacto |

|---|---|

| Preparación pandémica | Toallitas médicas, máscaras |

| Vehículos eléctricos (EV) | Paneles acústicos livianos |

| Embalaje de comercio electrónico | Capas de amortiguación no tejidas |

| Población envejecida | Toallitas de higiene y cuidado de los adultos |

Asia-Pacific liderará la demanda, con China e India escala la producción y el consumo. Mientras tanto, la Directiva de Plastics de un solo uso de la UE está reestructurando los materiales que podemos usar legalmente, forzando la innovación de los laboratorios de I + D para comprar pisos.

¿Qué podemos aprender de los éxitos y los fracasos?

Los estudios de casos ofrecen lecciones reales en diseño, marca y cumplimiento.

Las marcas como Tyvek de DuPont tuvieron éxito al centrarse en la durabilidad y la transpirabilidad, mientras que otras fallaron debido a los puntos ciegos de reciclabilidad.

Historias del campo

Éxito: DuPont Tyvek

- Utiliza flashspun PE no tejido.

- Ligero, impermeable, transpirable.

- Usado en sobres, envoltura de la casa, ppe.

Éxito: la línea ecológica de Freudenberg

- Incorpora botellas de PET recicladas.

- Objetivos de ESG transparentes y evaluación del ciclo de vida.

- Liderazgo del mercado de la UE en toallitas sostenibles 21 .

Falla: no reciclables de bajo costo

- Un proveedor europeo perdió contratos después de reclamar falsamente biodegradabilidad 22 .

- Los minoristas lanzaron la reacción posterior al cliente.

Una vez perdí un acuerdo porque un socio de proveedor ignoró los estándares de compostabilidad de la UE 23 . Desde entonces, siempre verifico dos veces los informes de prueba antes de hacer reclamos.

Conclusión

Los no tejidos representan el futuro de los textiles de ingeniería: versátiles, innovadores y cada vez más sostenibles. Su evolución, desde telas sencillas hasta materiales de alto rendimiento, refleja la creciente sofisticación de la industria.

Elbert Zhao

, Elbert Wipes Solutions

📧 [Correo electrónico protegido] | 🌐 www.elbertwipes.com

8 líneas de producción | 22 líneas de procesamiento | OEKO-TEX Certificado | Proveedor aprobado por Walmart

-

Explore las ventajas de las telas no tejidas para comprender su creciente importancia en diversas industrias y esfuerzos de sostenibilidad. ↩

-

Aprenda sobre el impacto de los textiles en la sostenibilidad y cómo contribuyen a un futuro más verde para nuestro planeta. ↩

-

Descubra cómo los materiales de ingeniería están revolucionando los textiles, ofreciendo soluciones innovadoras y mejorando la sostenibilidad. ↩

-

Conozca el papel crucial de ASTM en el establecimiento de estándares para telas no tejidas, garantizando la calidad y la consistencia en la industria. ↩

-

Descubra cómo los estándares de INDA dan forma a la industria no tejida y aseguran la producción y el rendimiento de alta calidad. ↩

-

Comprender las diferencias de velocidad de producción puede ayudarlo a elegir la tela adecuada para sus necesidades. Explore este enlace para obtener información detallada. ↩

-

Las opciones de personalización pueden afectar significativamente su proyecto. Descubra más sobre cómo los no tejidos ofrecen ventajas únicas en esta área. ↩

-

La rentabilidad es crucial para los proyectos conscientes del presupuesto. Aprenda cómo los non redes pueden ahorrarle dinero mientras satisfacen sus necesidades. ↩

-

Descubra los beneficios y aplicaciones de Hydroentanglement en la creación de telas suaves y duraderas, cruciales para varias industrias. ↩

-

Aprenda sobre los geotextiles perforados con aguja, su proceso de fabricación y cómo contribuyen a la construcción y los proyectos ambientales. ↩

-

Descubra soluciones de empaque ecológicas innovadoras que pueden ayudar a su negocio a cumplir con los objetivos de sostenibilidad. ↩

-

Conozca las ventajas de la tecnología SMS avanzada en aplicaciones médicas y su impacto en la atención al paciente. ↩

-

Explore cómo la capas de nanofibra mejora la eficiencia de la filtración y sus aplicaciones en varias industrias. ↩

-

Descubra los últimos avances en la tecnología de tela inteligente y cómo los sensores están revolucionando los textiles. ↩

-

Explore los últimos avances en aplicaciones de nanotecnología para comprender su impacto en diversas industrias e innovaciones. ↩

-

Conozca la tecnología detrás de los productos de incontinencia de detección de humedad y sus beneficios para los usuarios. ↩

-

Descubra las ventajas de las fibras biológicas en los no tejidos y cómo contribuyen a la sostenibilidad y al impacto ambiental. ↩

-

Explore las ventajas del PLA, una alternativa sostenible a los plásticos tradicionales y su impacto en la reducción de las emisiones de carbono. ↩

-

Aprenda cómo los sistemas de agua de circuito cerrado pueden reducir significativamente los desechos de agua y mejorar la sostenibilidad en los procesos de producción. ↩

-

Descubra la importancia de la certificación OEKO-TEX® para garantizar prácticas de producción textiles sostenibles y seguras. ↩

-

Explore las ventajas de las toallitas sostenibles y cómo contribuyen a los objetivos ambientales, mejorando su comprensión de los productos ecológicos. ↩

-

Comprender los estándares de biodegradabilidad es crucial para tomar decisiones informadas en textiles sostenibles y evitar errores costosos. ↩

-

Conozca los estándares de compostabilidad de la UE para garantizar el cumplimiento y mejorar la comercialización de su producto en Europa. ↩

6 respuestas

Hacer preguntas puede ser

algo realmente fastidioso si no comprendes algo por completo, sin embargo,

esta publicación proporciona una buena comprensión.

Aquí está mi sitio web :: สล็อต – http://www.artic-cooling.com ,

¡Aprecio que le guste!

Hola, creo que vi que visitaste mi blog, así que vine a "devolver el favor". ¡Estoy tratando de encontrar cosas para mejorar mi sitio! ¡Supongo que está bien usar algunas de tus ideas!

Gracias

¡Es un excelente ejemplo de cómo algo aparentemente sencillo puede tener mucho que ver entre bastidores! La mayoría de la gente no se da cuenta de cuánto influye el proceso de fabricación en el producto final. El hecho de que los mismos materiales básicos puedan producir resultados totalmente diferentes, como toallitas suaves frente a geotextiles superresistentes, demuestra la precisión y la experiencia que requiere la producción de no tejidos.

¡Gracias por tus comentarios! ¡Profesional!