Worried about swirl marks ruining your car’s finish? Discover how microfiber towels interact with paint surfaces and learn techniques to eliminate scratch risks 1 forever.

High-quality microfiber towels won’t scratch cars when used correctly. Their ultra-fine fibers trap contaminants below the surface, preventing direct contact with paint. Scratch risks arise from improper technique, contaminated towels, or low-quality materials – not the microfiber itself.

Understanding why microfiber towels are generally safe requires examining the science behind their design. Let’s explore key factors determining scratch potential.

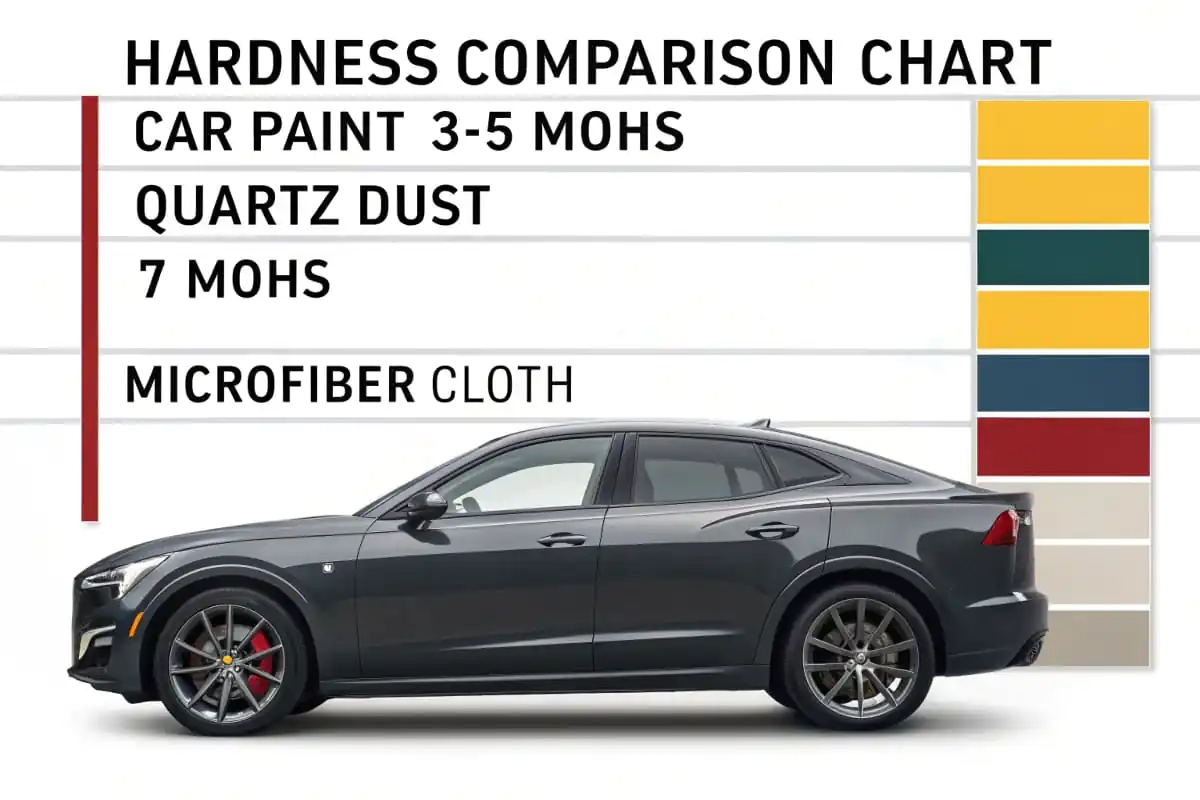

What Determines Scratch Risk: Paint Hardness vs Contaminants?

Imagine rubbing sandpaper on soft paint. The real scratch culprit isn’t your towel – it’s trapped particles grinding against the surface.

Car paint (3-5 Mohs hardness) is softer than common contaminants like quartz dust (7 Mohs). Microfiber prevents scratches by encapsulating debris within its fibers before they contact the paint surface. Proper lubrication is essential for this protection 2 .

Material Hardness and Protection Mechanisms

Microfiber creates a protective buffer zone through three key actions:

| Mechanism | Function | Scratch Prevention Impact |

|---|---|---|

| Fiber Splitting | Ultra-fine filaments (1/100 human hair) | Creates more debris-trapping pockets |

| Capillary Action | Wicks particles into fiber core | Removes contaminants from paint contact |

| Electrostatic Lift 3 | Attracts dust via static charge | Captures airborne particles during drying |

Critical considerations :

- Lubrication dependency : Towels need soapy water or quick detailer to create slippery surface

- Contaminant capacity : Higher GSM towels (800+) hold more debris before releasing particles

- Fiber degradation : Worn towels lose split ends, reducing particle entrapment efficiency

Always perform the “bag test”: Seal hand in towel-filled plastic bag – quality microfiber should grip skin through the plastic.

How Does Towel Design Impact Scratch Safety?

Not all microfiber is created equal. Your towel’s construction could be inviting scratches without your knowledge.

Towel safety depends on pile height 4 , weave type, and edge finishing. Plush 80/20 blend towels (80% polyester/20% polyamide) with laser-cut edges offer maximum scratch protection, while low-pile waffle weaves risk dragging debris across paint.

Engineering Scratch-Proof Towels

Design elements directly influence scratch potential:

Pile Height & Density

- Short pile (<3mm): Higher pressure per fiber – riskier on soft paints

- Long pile (5-8mm): Distributes pressure, better contaminant retention

- Density matters: 800+ GSM towels provide cushioning effect

| Weave Type Performance | Weave Type | Best Use | Scratch Risk Level |

|---|---|---|---|

| Plush Terry | Final drying | ★☆☆ (Lowest) | |

| Waffle | Glass/wheels | ★★☆ (Moderate) | |

| Twist Loop | Interior | ★★★ (Highest) |

Edge Treatment Criticality

- Laser-cut edges 5 : Sealed fibers won’t unravel

- Overlocked edges 6 : Thread binding reduces fraying

- Raw edges 7 : Absolute scratch hazard – avoid completely

Premium towels incorporate color-coded edging to prevent accidental wheel-to-paint contamination.

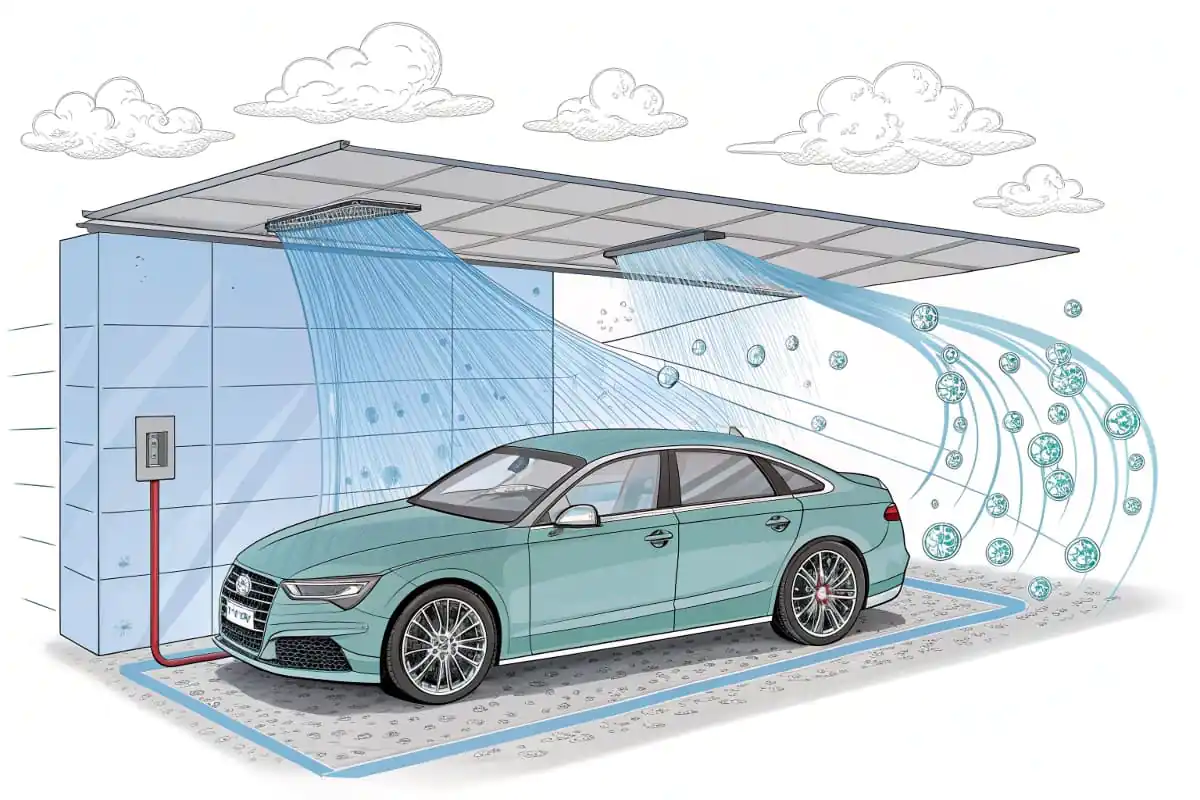

What’s the Safest Car Drying Technique?

Drying causes 80% of towel-induced scratches. Transform this high-risk step into a scratch-proof process.

The “flood rinse” method is safest: Sheet water off panels, then glide a soaked 800GSM towel 8 using only its weight. Never rub or apply pressure. For coated cars, filtered-air blowers eliminate towel contact entirely.

Mastering Scratch-Free Drying

Implement these professional techniques:

Patting vs Flooding Method

- Patting: High contamination risk as particles press against paint

- Flooding: Towel floats on water layer – suspended debris away from surface

Step-by-Step Flooding Technique

- Rinse with open hose (no nozzle) to create water sheet

- Fold towel into 1/4 size with plush side out

- Place unfolded edge at top of panel

- Drag downward using towel’s own weight

- Flip to clean section after each pass

Contactless Drying Priority

For ceramic coatings or PPF:

- Air blower (filtered air only) 9

- Flood method with coating-specific towel 10

- Patting (not recommended) 11

Always maintain a “lubrication layer” – never dry completely bare paint. Keep a spray bottle of quick detailer for rewetting areas.

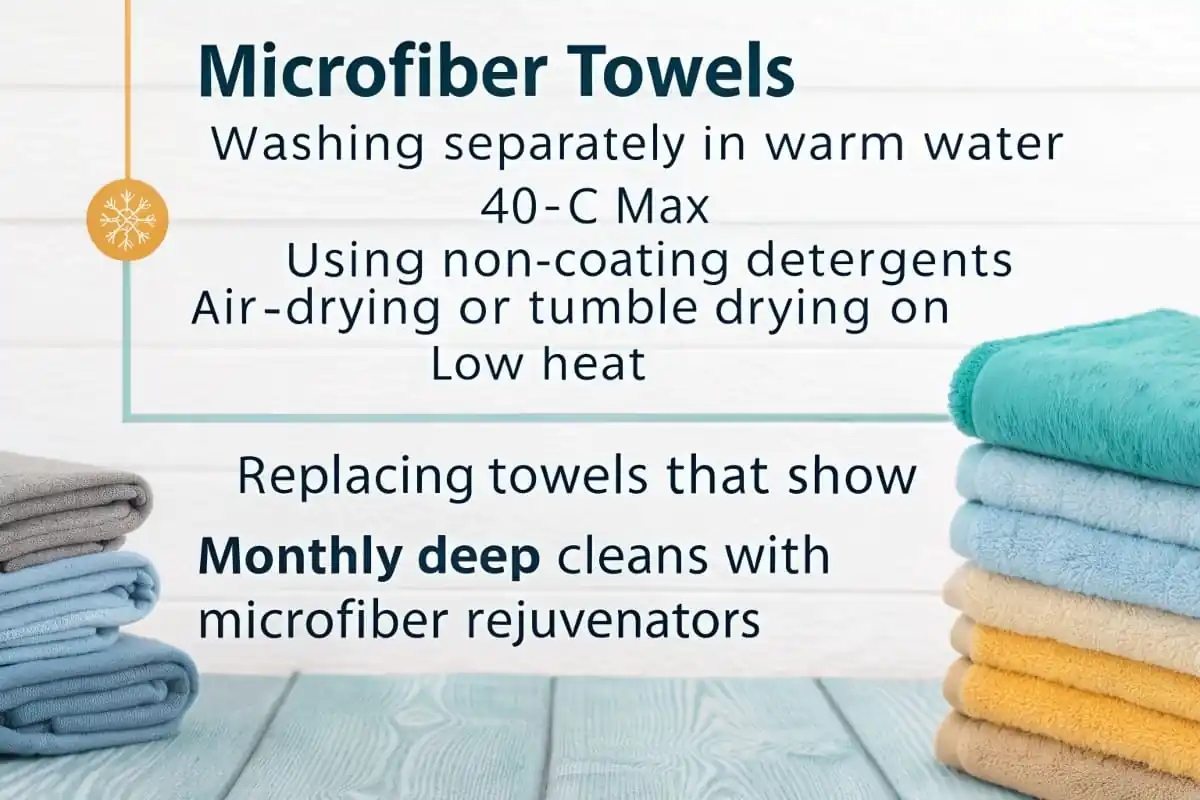

How Should I Maintain Microfiber Towels?

Your clean-looking towel might be a sandpaper substitute. Proper maintenance separates safe towels from scratch monsters.

Wash microfiber separately in warm water (40°C max) using non-coating detergents. Air-dry or tumble dry low. Replace towels showing linting, stiffness, or embedded particles. Perform monthly deep cleans with microfiber rejuvenators .

Extending Towel Life Safely

Critical maintenance protocols:

| Washing/Drying Specifications | Process | Requirement | Why It Matters |

|---|---|---|---|

| Wash Temp | ≤40°C (104°F) | Prevents fiber melting | |

| Detergent | Surfactant-free | Avoids coating contamination | |

| Drying | Low heat (<60°C) | Preserves fiber splitting | |

| Storage | Sealed containers | Prevents dust contamination |

Damage Diagnosis & Replacement

- Linting: Fiber breakdown – replace immediately 12

- Stiffness: Oil buildup – requires deep cleaning 13

- Grit feeling: Contaminant saturation – retire towel 14

- Water repelling: Chemical contamination – strip wash needed 15

- Final rinse with distilled water

- Add citric acid (0.5%) to rinse cycle

- Use water softeners in wash

For ceramic coating towels: Dedicate towels exclusively to coated vehicles and wash after every 2-3 uses. Never use all-purpose towels on coatings.

Conclusion

Microfiber towels prevent scratches when selected wisely and maintained properly. Combine quality materials with safe techniques for flawless results every wash.

Elbert Zhao

Founder, Elbert Wipes Solutions

📧 [email protected] | 🌐 www.elbertwipes.com

8 production lines | 22 processing lines | OEKO-TEX® certified

- This resource will provide you with effective techniques to avoid scratches and maintain your car’s pristine appearance. ↩

- Learn why lubrication is crucial for maximizing the effectiveness of microfiber towels in protecting surfaces. ↩

- Understanding Electrostatic Lift can enhance your cleaning efficiency by ensuring effective dust capture. ↩

- Exploring towel design can help you choose the right microfiber for scratch-free cleaning. ↩

- Explore this link to understand how laser-cut edges enhance towel durability and reduce scratch risks. ↩

- Explore this link to understand how overlocked edges enhance durability and reduce scratch risks in car drying towels. ↩

- Understanding the risks of raw edges can help you choose safer, more effective towels for car care. ↩

- Explore the advantages of 800GSM towels for car drying to ensure a scratch-free finish and optimal performance. ↩

- Explore this link to find top-rated air blowers that ensure a scratch-free drying experience for your vehicle. ↩

- Explore this resource to learn expert tips on maximizing the effectiveness of the flood method for a scratch-free finish. ↩

- Understanding the risks of patting can help you avoid damaging your car’s finish and ensure a scratch-free drying process. ↩

- Understanding linting in microfiber towels helps maintain their effectiveness and prolongs their lifespan, ensuring optimal performance. ↩

- Explore this resource to learn proven techniques for deep cleaning microfiber towels, ensuring longevity and optimal performance. ↩

- Understanding contamination signs helps maintain towel quality and protect your surfaces from scratches. ↩

- Understanding strip washes can help you effectively restore your towels, ensuring they perform their best and last longer. ↩

- Exploring hard water solutions can help you maintain the quality of your towels and enhance their performance. ↩